SANXIS TECHNOLOGY (HONG KONG) LTD

Labarai

-

Menene PCB SMT Stencil (Sashe na 6)

Ƙayyadaddun tsari na ƙirar SMT stencil ya haɗa da abubuwa masu mahimmanci da matakai don tabbatar da inganci da daidaito na stencil. Yanzu bari mu koyi game da mahimman abubuwan da ke cikin samar da stencil na SMT: 1. Frame 2. Tsaki 3. Stencil Sheet 4. M 5. Tsarin Tsarin Stencil 6. Tsarin Stencil 7. Tashin hankali 8. Alamar maki 9. Zaɓin kauri na Stencil

-

Bambancin Tsakanin Gwajin Binciken Flying Probe da Gwajin Gyaran Gwaji

Dukanmu mun san cewa a lokacin da ake samar da allunan da'ira na PCB, babu makawa a sami lahani na lantarki kamar gajeriyar da'ira, buɗaɗɗen da'ira, da ɗigogi saboda abubuwan waje. Don haka, don tabbatar da ingancin samfur, allon kewayawa dole ne a yi gwaji mai tsauri kafin barin masana'anta.

-

Ma'anar "LAYER" a masana'antar PCB.(Sashe na 4)

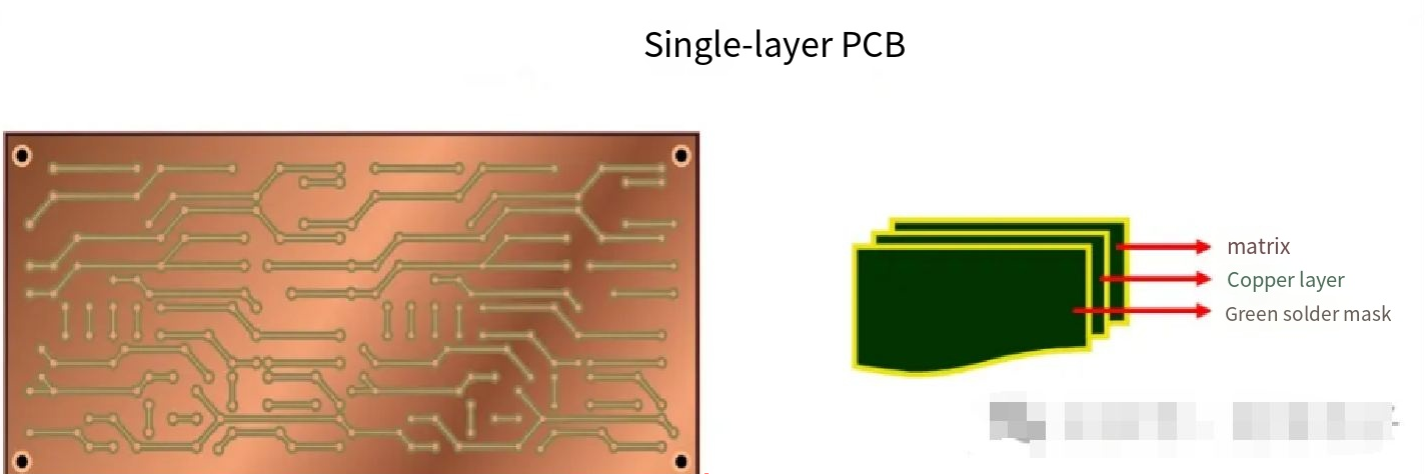

A cikin wannan sabon, za mu koyi game da ilimin PCB mai Layer Layer da PCB mai gefe biyu.

-

Ma'anar "LAYER" a masana'antar PCB.(Sashe na 3)

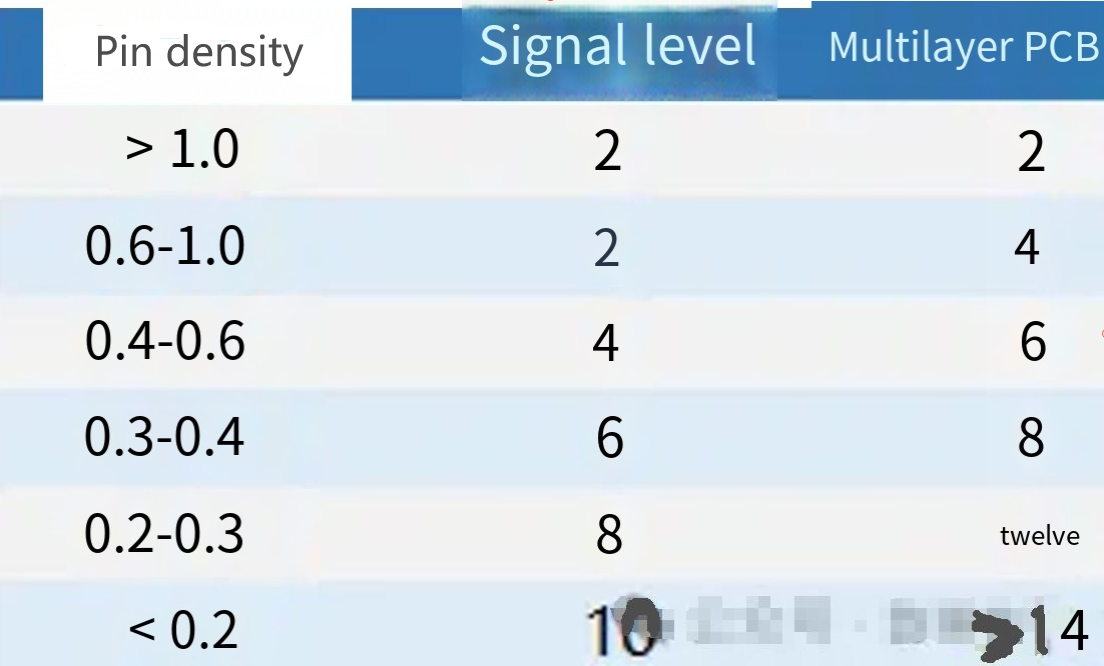

A yau, bari mu yi magana game da sauran dalilin da ke ƙayyade yawan yadudduka da aka tsara PCB don samun.

-

Mu Ga Kayan Gwajin Kamfaninmu

A yau, bari mu dubi kayan gwaji a masana'antar mu waɗanda ke ba da tabbacin ingancin samfuran PCB da muke samarwa.

-

Barka da Baƙi na Ƙasashen Waje Zuwa Masana'antarmu!

A kan 15th Oct. Abokin ciniki form NZ zo ziyarci mu factory a cikin ShenZhen.

-

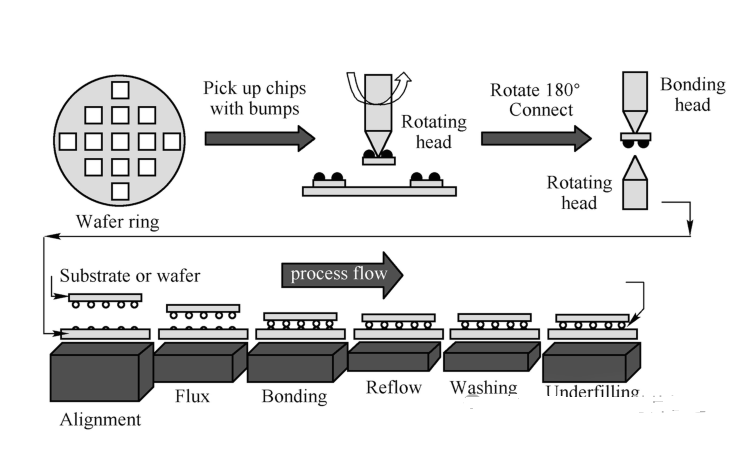

Gabatarwar Flip Chip a cikin Fasahar SMT. (Kashi na 4)

Bari mu ci gaba da koyon tsari game da sanya guntu. 1. Karɓar Chips tare da Bump 2. Chip Orientation 3. Chip Daidaita 4. Chip bonding 5. Maimaitawa 6. Wanka 7. Rashin cikawa 8. Yin gyare-gyare

-

Kunshin Chip Madaidaicin Nau'in Substrate

Anan akwai tebur na marufi na Chip daidai nau'ikan nau'ikan madauri

-

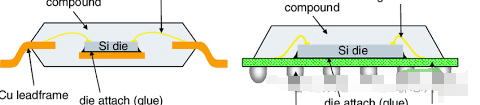

Menene Abubuwan Marufi?

Kamar yadda aka nuna a cikin adadi da ke sama, sarƙoƙi Substrater sun kasu kashi uku: Organic Substrates, da substrates, da substrater.

-

Menene babban Tg kuma menene fa'idodin PCB tare da ƙimar Tg mai girma?

A yau, zan gaya muku menene ma'anar TG, kuma menene fa'idodin amfani da babban TG PCB.

Hausa

Hausa English

English Українська

Українська नेपाली

नेपाली Azərbaycan

Azərbaycan Беларус

Беларус සිංහල

සිංහල O'zbek

O'zbek Yoruba

Yoruba Divih

Divih Ελληνικά

Ελληνικά اردو

اردو Español

Español Português

Português русский

русский Deutsch

Deutsch Tiếng Việt

Tiếng Việt বাংলা

বাংলা हिन्दी

हिन्दी Pilipino

Pilipino Türk

Türk عربى

عربى