SANXIS TECHNOLOGY (HONG KONG) LTD

Labarai

-

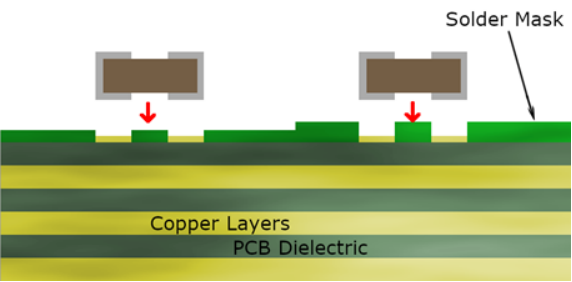

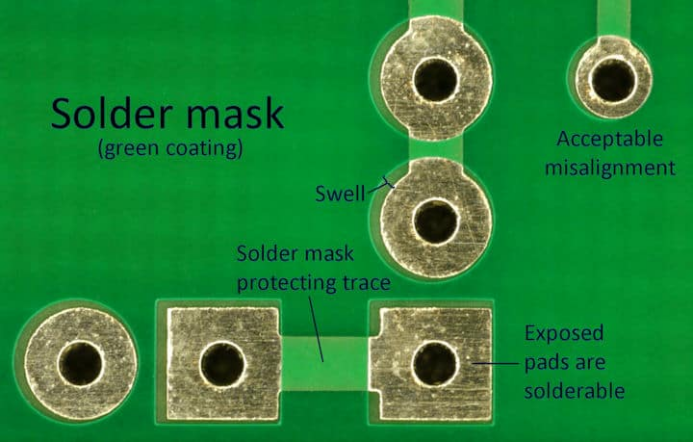

PCB Solder Mask Ma'aunin Kauri

Gabaɗaya, kaurin abin rufe fuska a tsakiyar layin gabaɗaya bai fi microns 10 ba, kuma matsayi a ɓangarorin biyu gabaɗaya bai fi 5 microns ba, wanda a da aka tsara a cikin ma'auni na IPC, amma. yanzu ba a buƙata ba, kuma takamaiman buƙatun abokin ciniki za su yi nasara.

-

Dalilan Solder Mask akan PCB

A cikin tsarin sarrafawa da samarwa na PCB, ɗaukar hoto tawada abin rufe fuska yana da matukar mahimmanci.

-

Menene Sirrin Launi a Mashin Solder PCB? (Kashi na 2.)

Green tawada na iya yin ƙarami kuskure, ƙaramin yanki, na iya yin daidaici mafi girma, kore, ja, shuɗi fiye da sauran launuka suna da daidaiton ƙira mafi girma.

-

Menene Sirrin Launi a Mashin Solder PCB? (Kashi na 1.)

PCB solder mask za a iya nuna a daban-daban launuka, ciki har da kore, fari, blue, baki, ja, rawaya, matte, purple, chrysanthemum, haske kore, matte baki, matte kore da sauransu.

-

Menene Solder Manufacturer?

Mashin solder muhimmin mataki ne a cikin tsarin kera PCB.

-

Dalilan Amfani da Ƙirƙirar Zinare na Immersion

Dalilan Amfani da Ƙirƙirar Zinare na Immersion

-

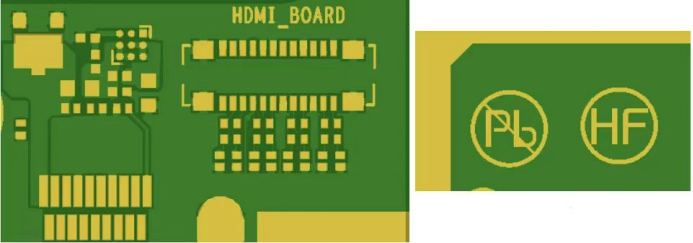

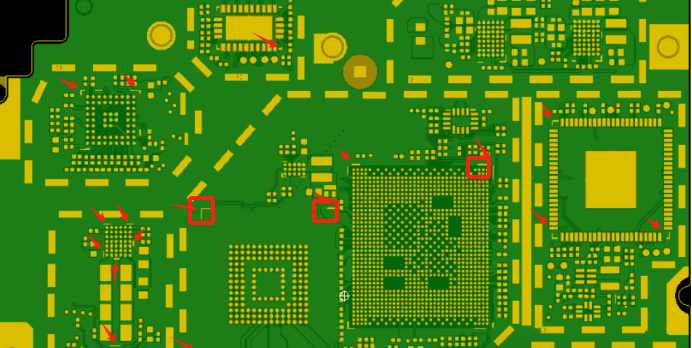

Sabbin Kayayyakinmu Tare da Zinare Immersion

Anan ga sabon samfurin mu, wanda ke amfani da dabarun kera gwal na nutsewa da yatsa na zinari.

-

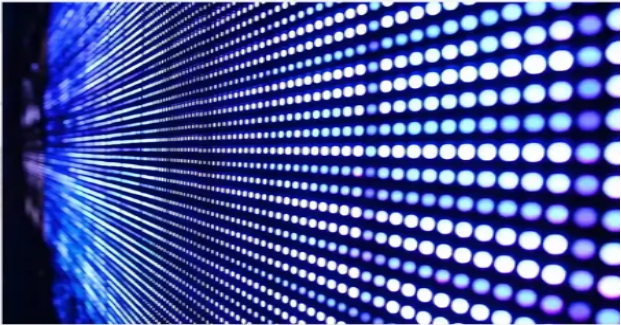

Soul of LED Screen, HDI PCB

Ko wasan kwaikwayo na tauraro ne, tasirin musamman na 3D na cikin gida, ko wasu gine-ginen ofis sama da allon talla, mafi haske da haske allo, mafi tsananin buƙatun PCB.

-

Mene ne abũbuwan amfãni da rashin amfani na Golden Waya Matsayi

Kamar yadda muka sani, da zinariya waya matsayi tsari ne yafi amfani a SMT faci masana'antu, don haka menene abũbuwan amfãni ko rashin amfani da zinariya waya matsayi ga farantin yin?

-

Menene Matsayin Waya Golden Waya

Matsayin waya na gwal hanya ce ta saka abubuwa wanda galibi ana amfani dashi a babban matakin HDI PCB.

Hausa

Hausa English

English Українська

Українська नेपाली

नेपाली Azərbaycan

Azərbaycan Беларус

Беларус සිංහල

සිංහල O'zbek

O'zbek Yoruba

Yoruba Divih

Divih Ελληνικά

Ελληνικά اردو

اردو Español

Español Português

Português русский

русский Deutsch

Deutsch Tiếng Việt

Tiếng Việt বাংলা

বাংলা हिन्दी

हिन्दी Pilipino

Pilipino Türk

Türk عربى

عربى